Page 29 - Intel - Powering Innovation to scale

P. 29

For SMEs and manufacturers, upgrading machinery with intelligence and automation to adopt Industry 4.0 is complex and expensive considering the investments in sensors, hardware, and the dependency to run the analytics on the cloud.

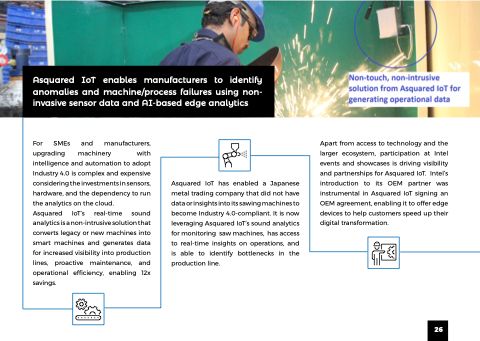

Asquared IoT’s real-time sound analytics is a non-intrusive solution that converts legacy or new machines into smart machines and generates data for increased visibility into production lines, proactive maintenance, and operational efficiency, enabling 12x savings.

Asquared IoT has enabled a Japanese metal trading company that did not have data or insights into its sawing machines to become Industry 4.0-compliant. It is now leveraging Asquared IoT’s sound analytics for monitoring saw machines, has access to real-time insights on operations, and is able to identify bottlenecks in the production line.

Apart from access to technology and the larger ecosystem, participation at Intel events and showcases is driving visibility and partnerships for Asquared IoT. Intel’s introduction to its OEM partner was instrumental in Asquared IoT signing an OEM agreement, enabling it to offer edge devices to help customers speed up their digital transformation.

Asquared IoT enables manufacturers to identify anomalies and machine/process failures using non- invasive sensor data and AI-based edge analytics

26